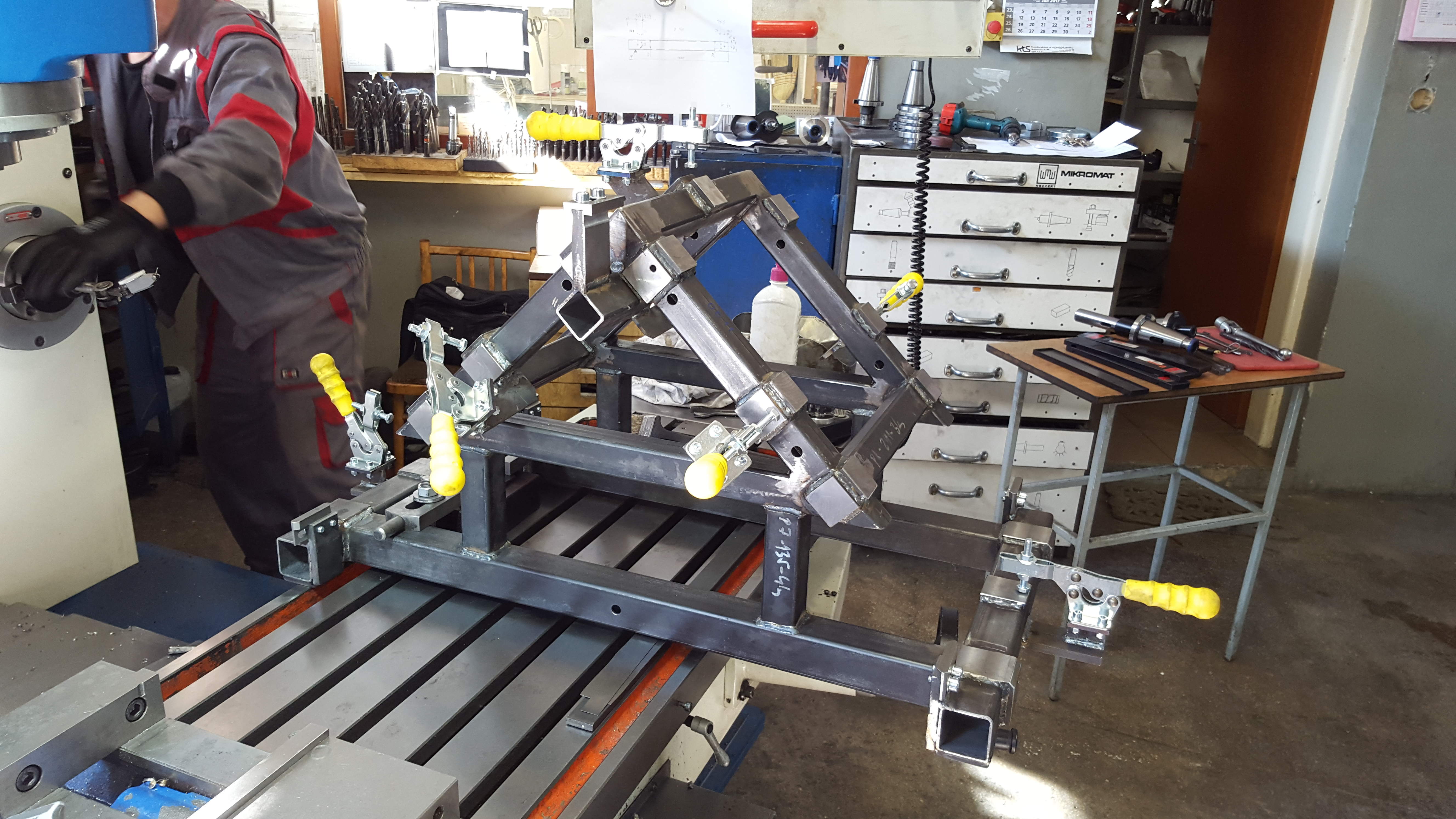

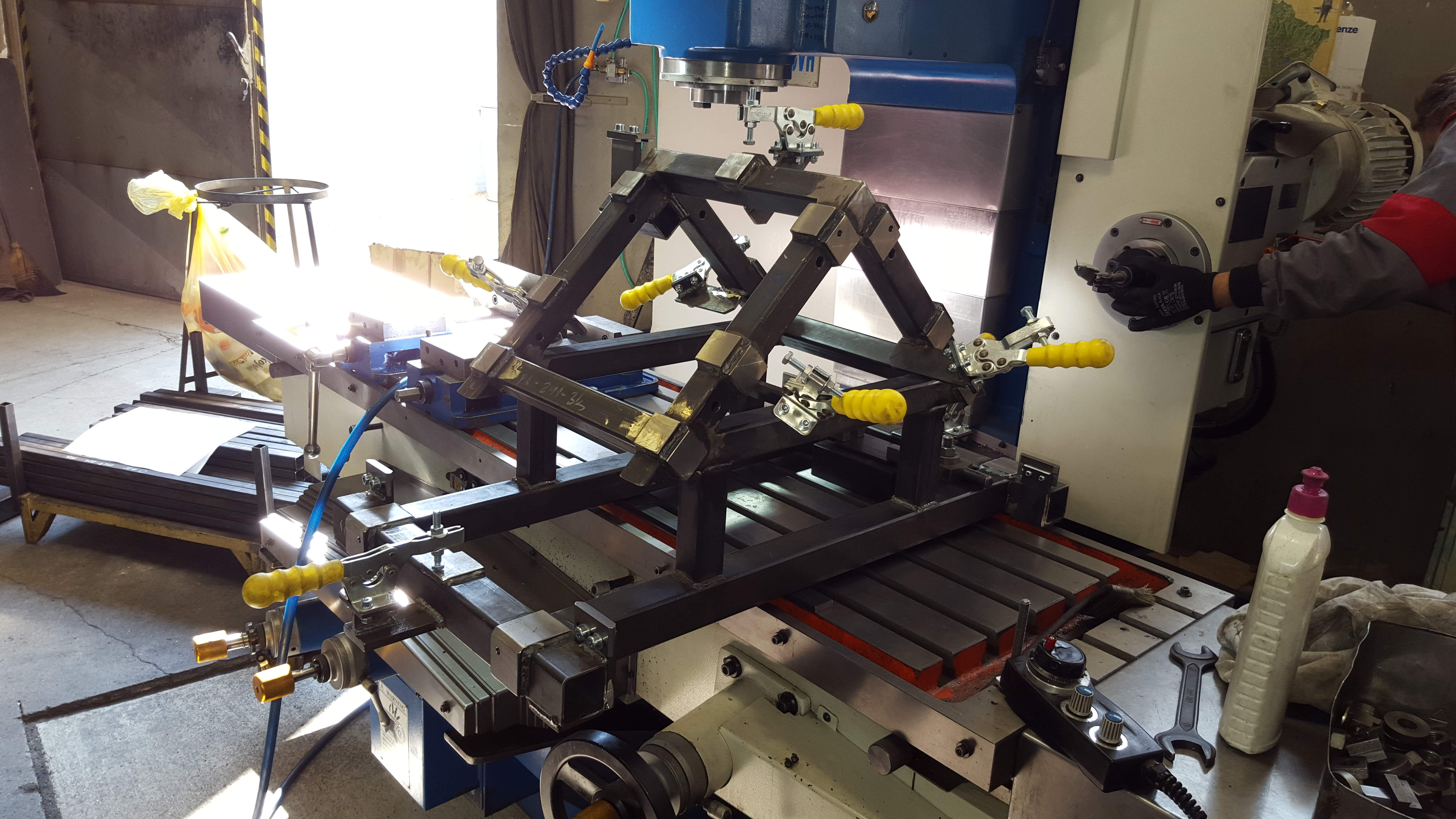

Welding jigs are

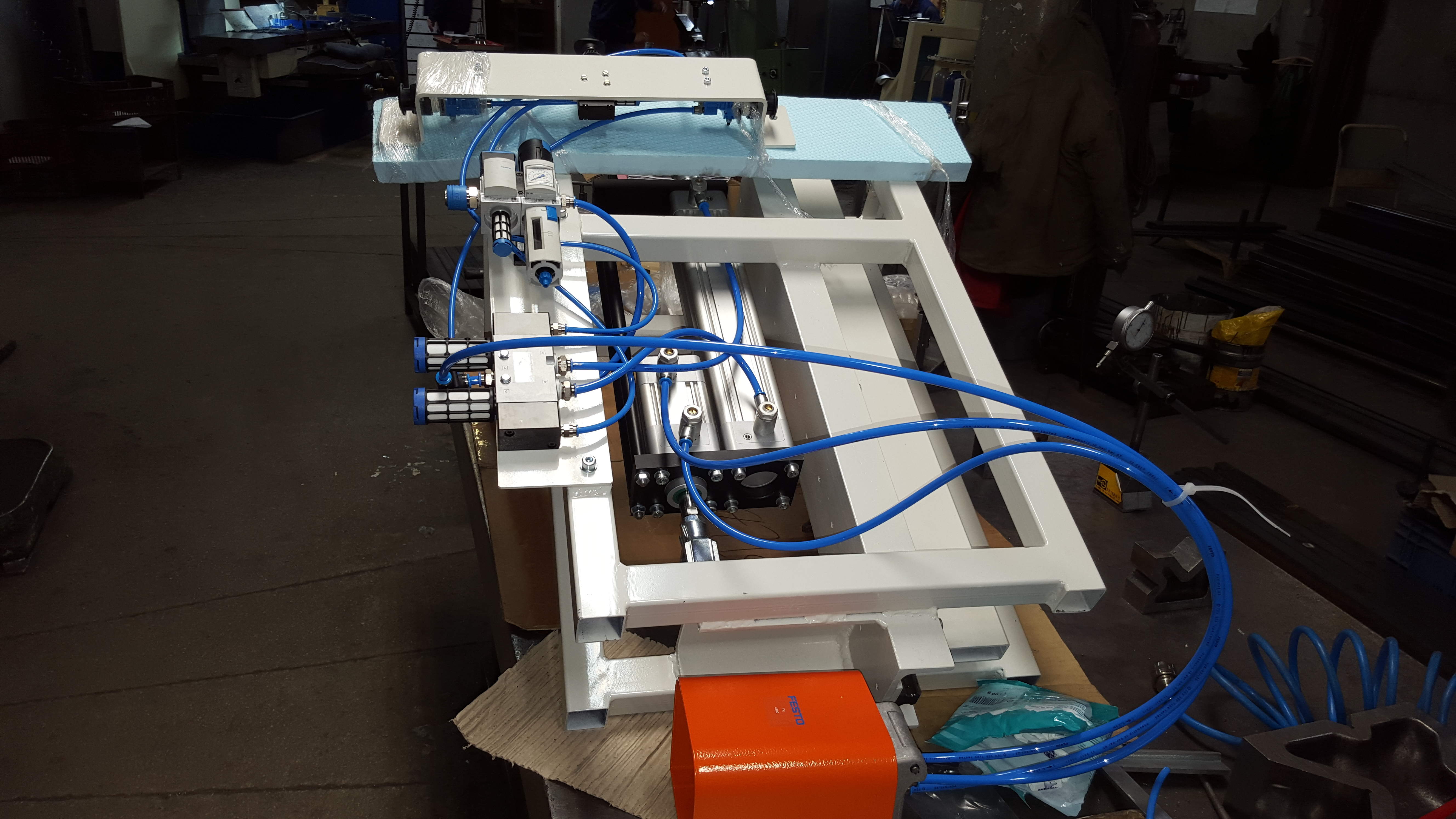

peripheral devices of welding workstations designed for precise positioning of

welded parts. The welding jig may be fixed at the workstation or on a suitable

type of positioner equipped with a jig with one or more axes, thereby providing

better accessibility to the welding locations. Our company has rich experience

in development, design and production of jig such as:

- Welding jigs for manual welding

- Welding jigs for robotic welding stations

- Fixed or rotary table version

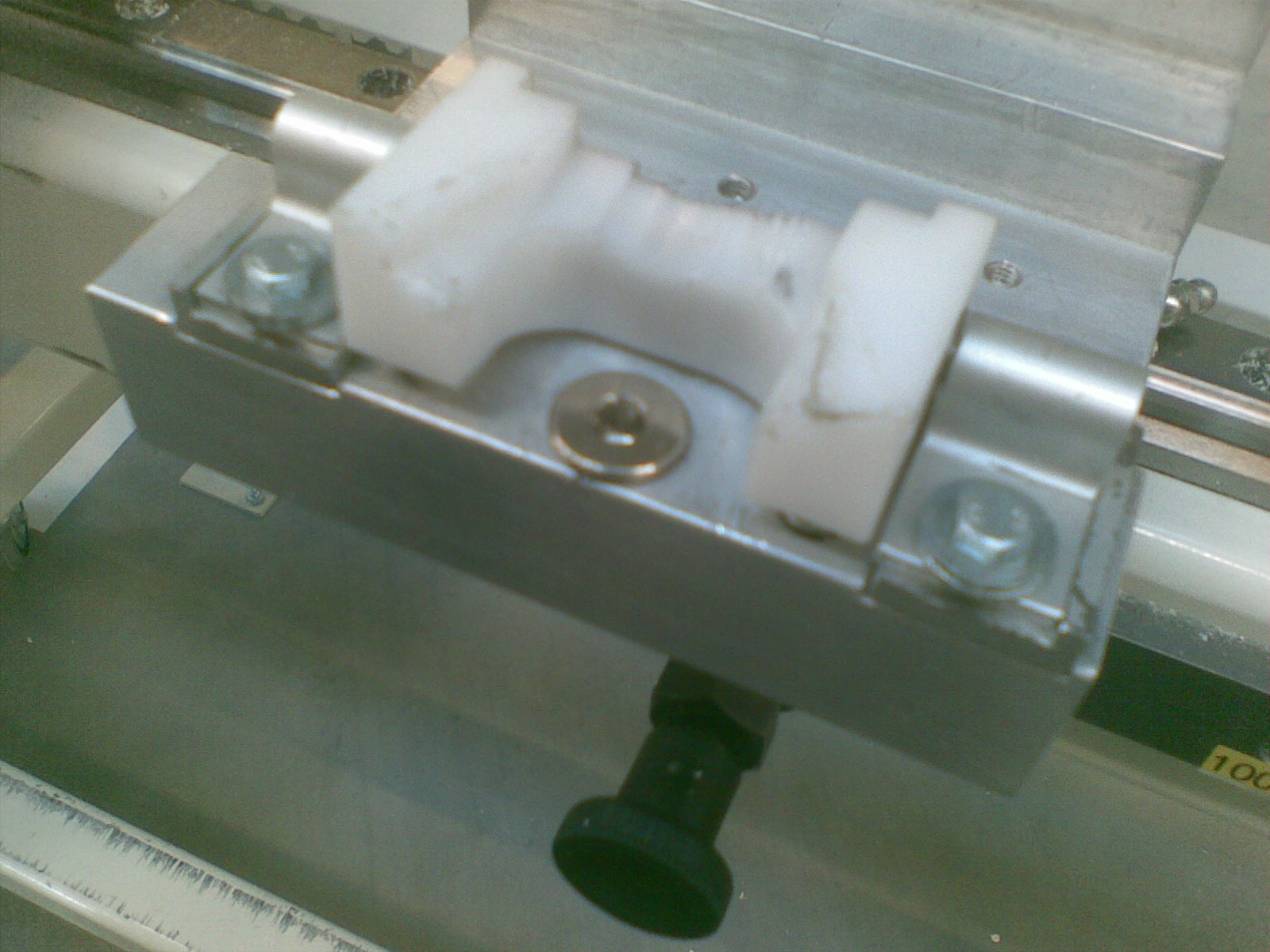

- Mechanical or pneumatic clamping of parts

The diversity of our clients' products requires a variety of jigs solutions. That is why we try to adapt our welding jigs to increasingly demanding client requirements and innovate their production processes. The construction of the jig assembly is done in the CAD system, by display of 3D representation of the models of individual modules and welded parts. The use of particular elements is decided on the basis of mutual dimensional and functional compatibility. Because of the necessary availability and accessibility of the robot to all welding locations, the jig assembly is tested in order to achieve the desired availability of welding points (surfaces) and determine their optimal position. If it is necessary, we can also design and manufacture a suitable base for the welding robot.

Basic functions of our welding jigs:

- precise positioning and clamping (fixation) of welded parts

- allow fast insertion and removal of parts (manual or robotic)

- ensuring optimum accessibility of the welding torch or welding scissors to the welded areas.

The design of the welding jigs depends on several factors, including:

- shape and dimensions of welded parts

- weight of welded parts

- material of welded parts

- the process of joining them together into the resulting assembly

- method of inserting and removing parts

- production cycle

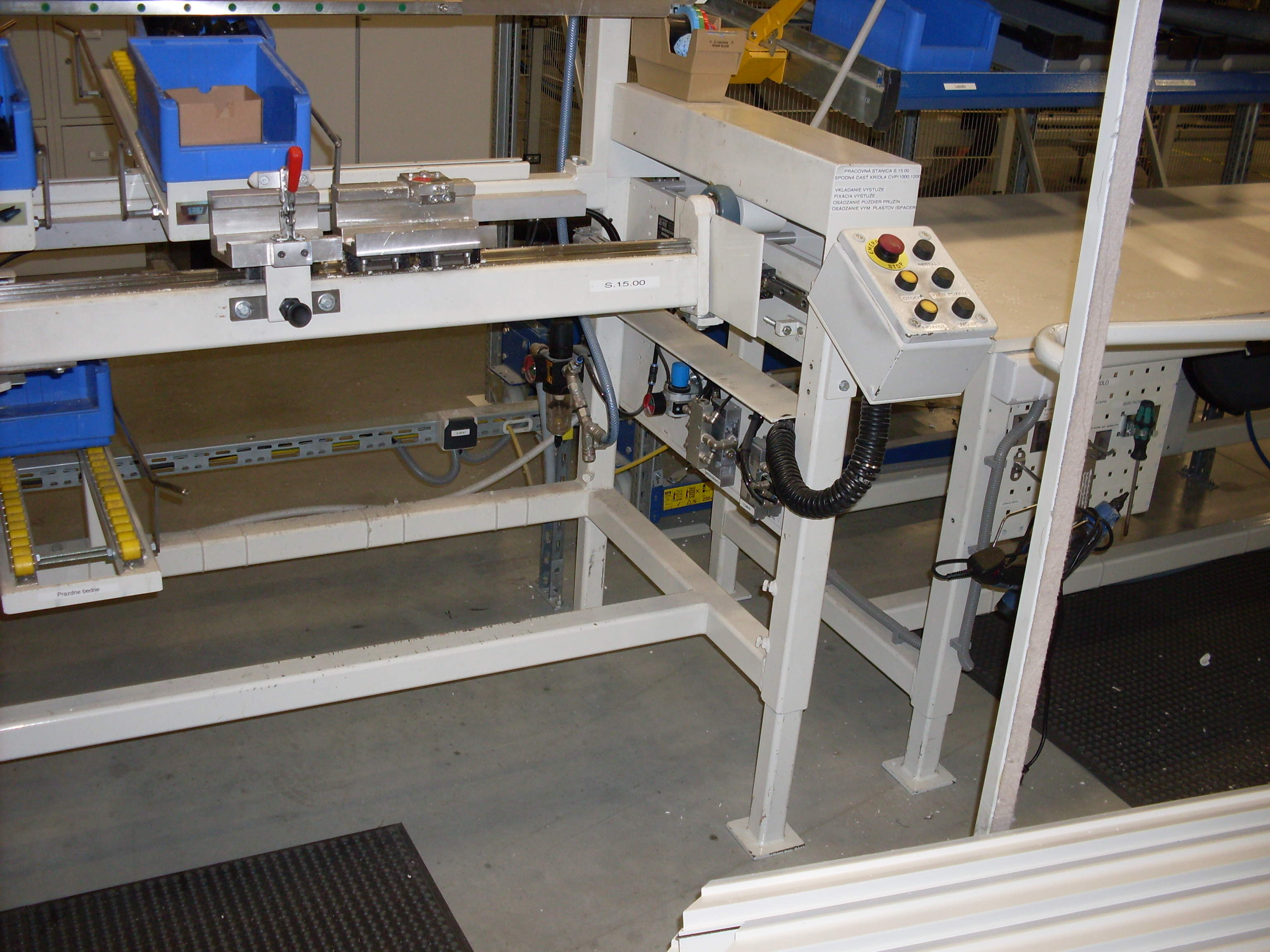

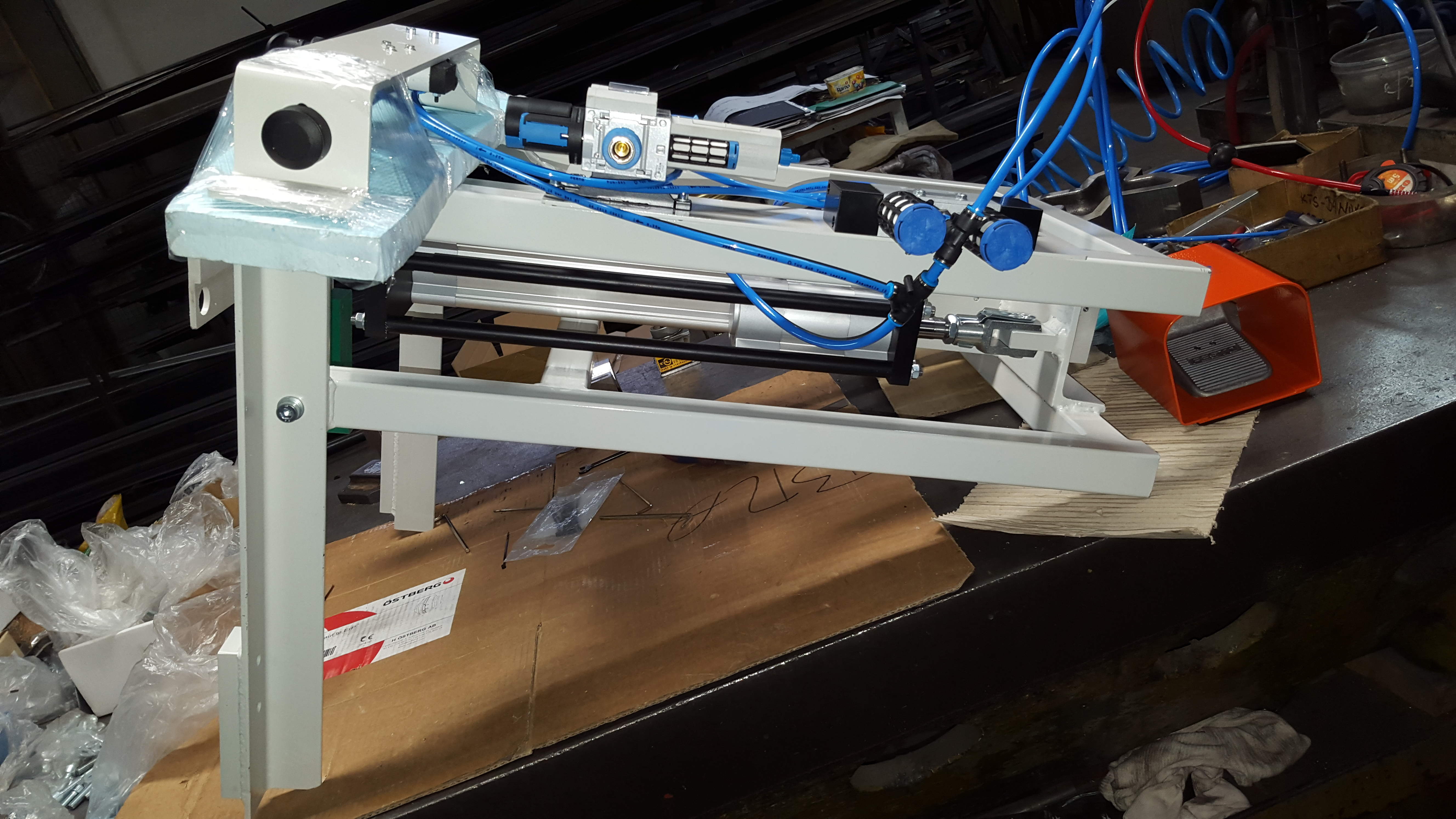

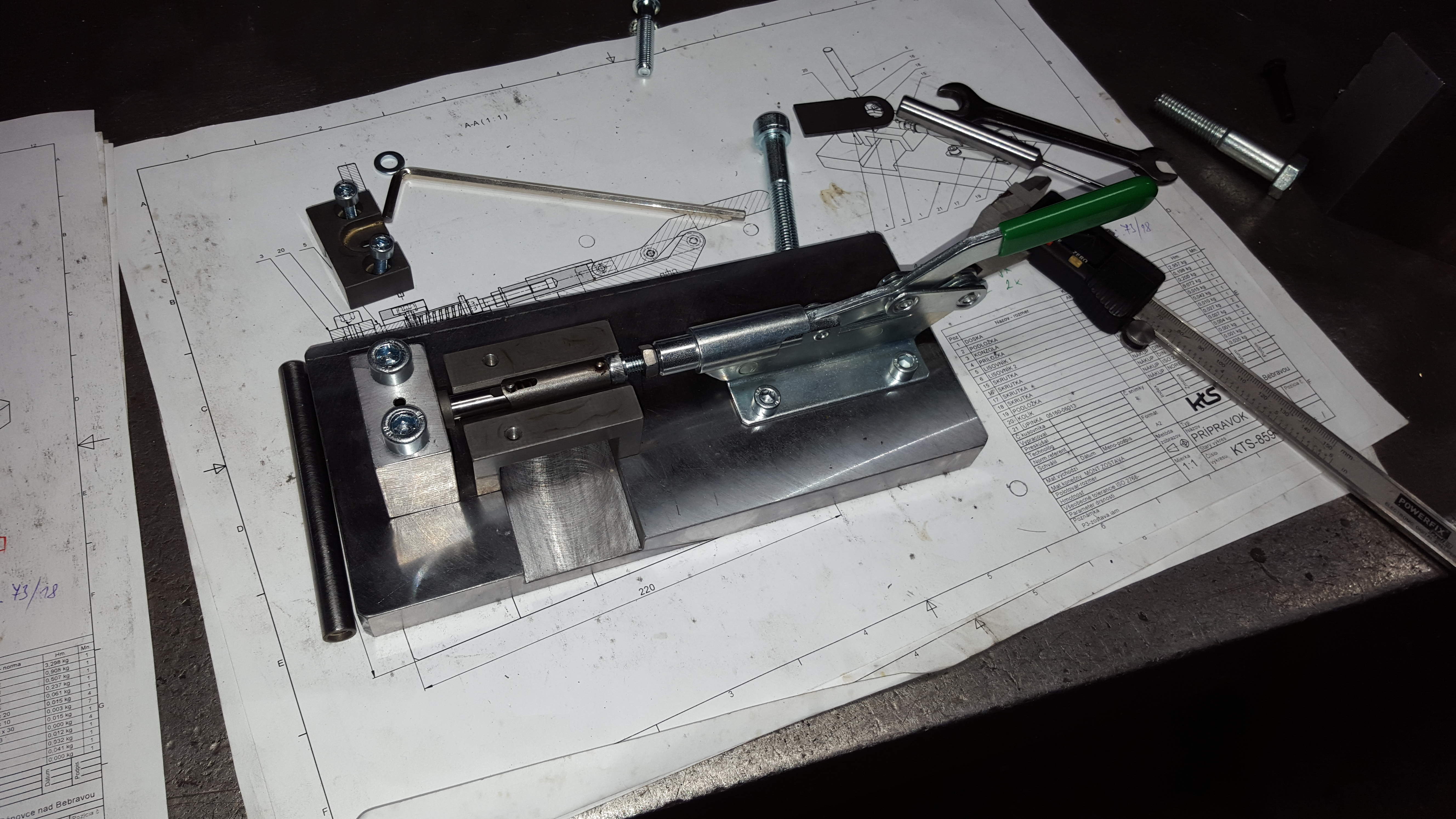

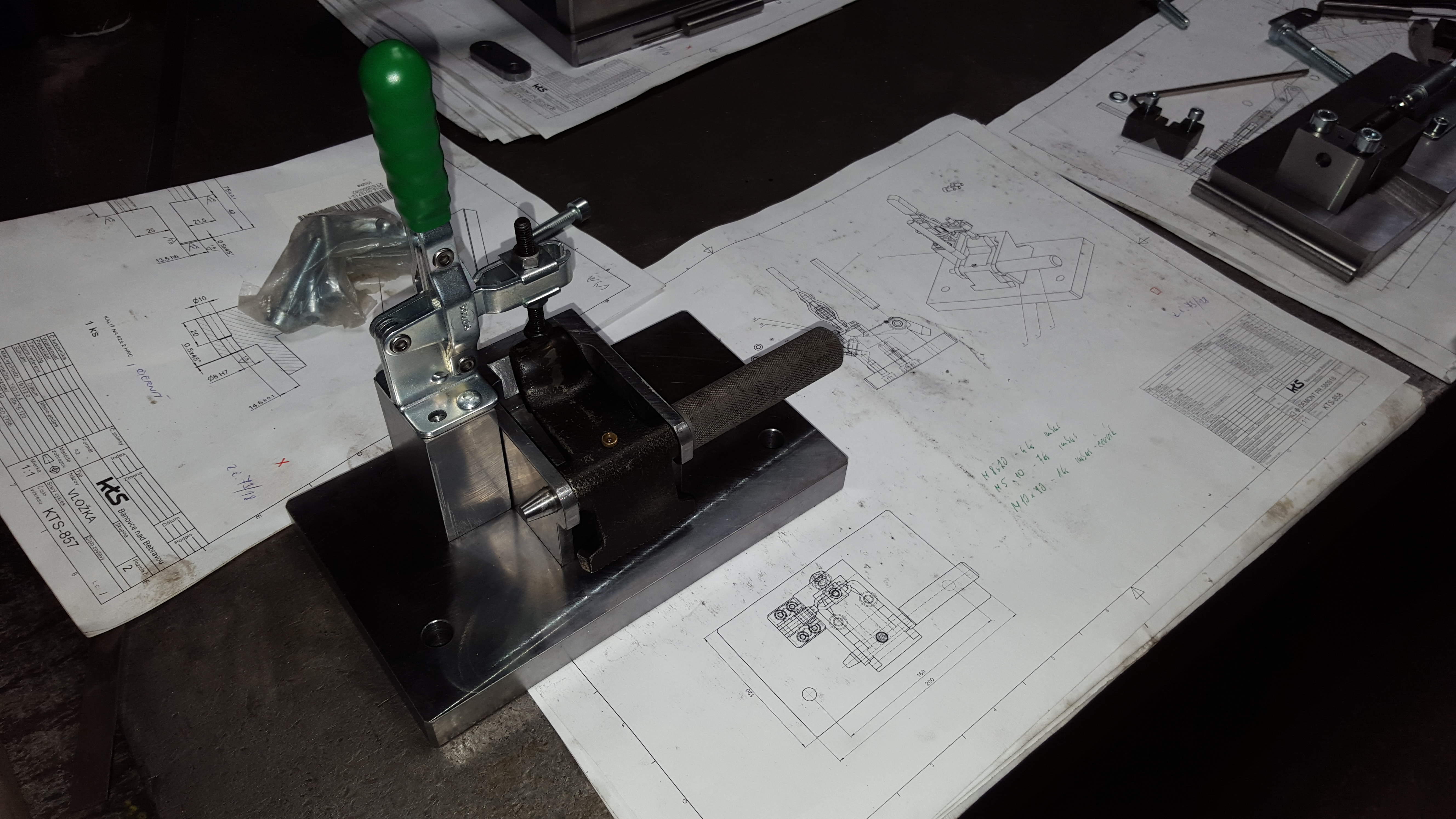

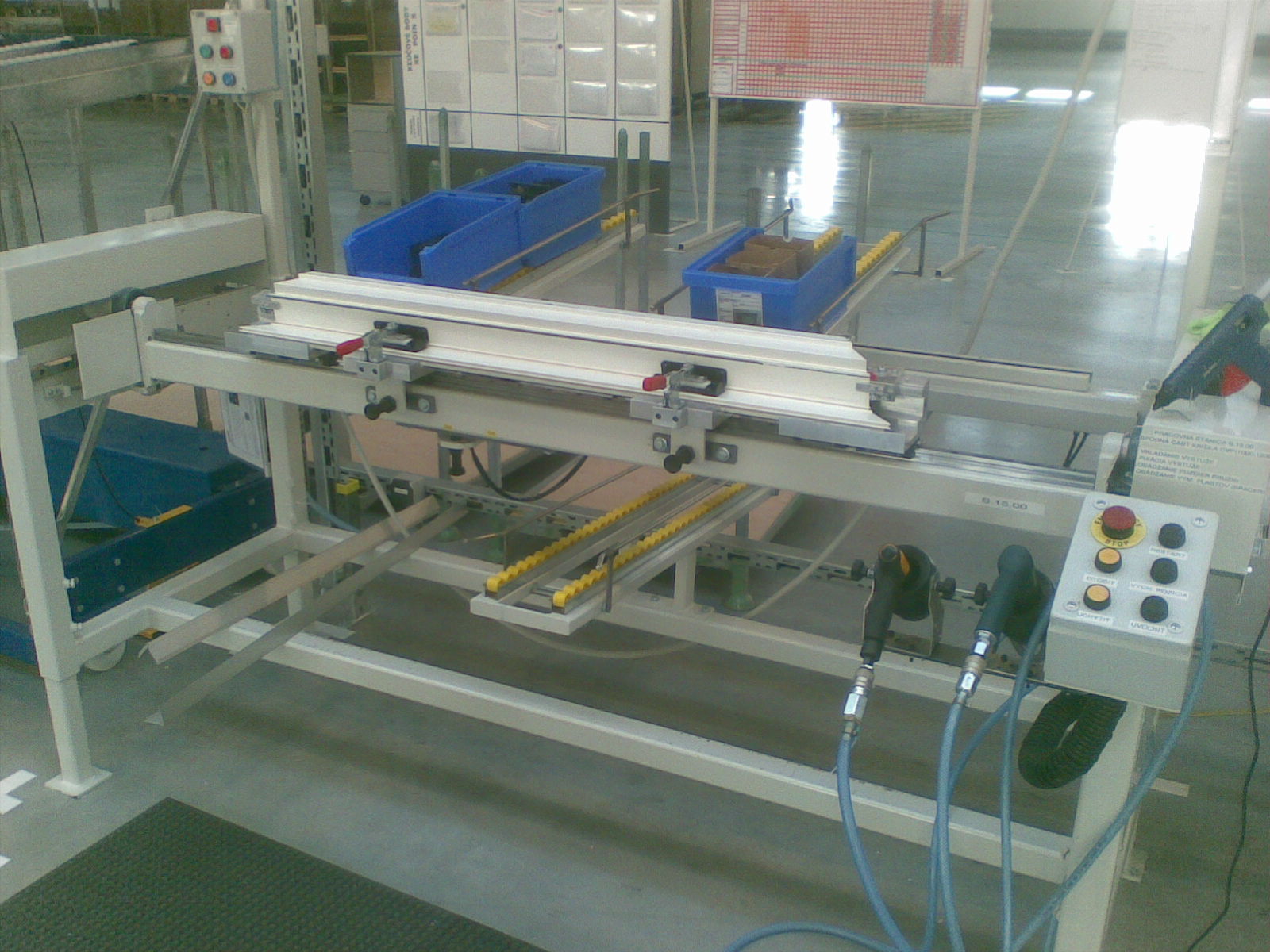

Assembly is the final and in most cases the most difficult stage of the production process. The decisive factor affecting assembly is not only the quality and reliability of the products, but also the continuous production time, labor productivity and efficiency of the whole system. The decisive factor in the development of automated assembly processes is the technology that brings new solutions and leads to the improvement and improvement of labor productivity, mechanization and automation. The task of assembly and disassembly jigs is to increase the number of products in a shorter working time. Our company specializes in the development, design and production of:

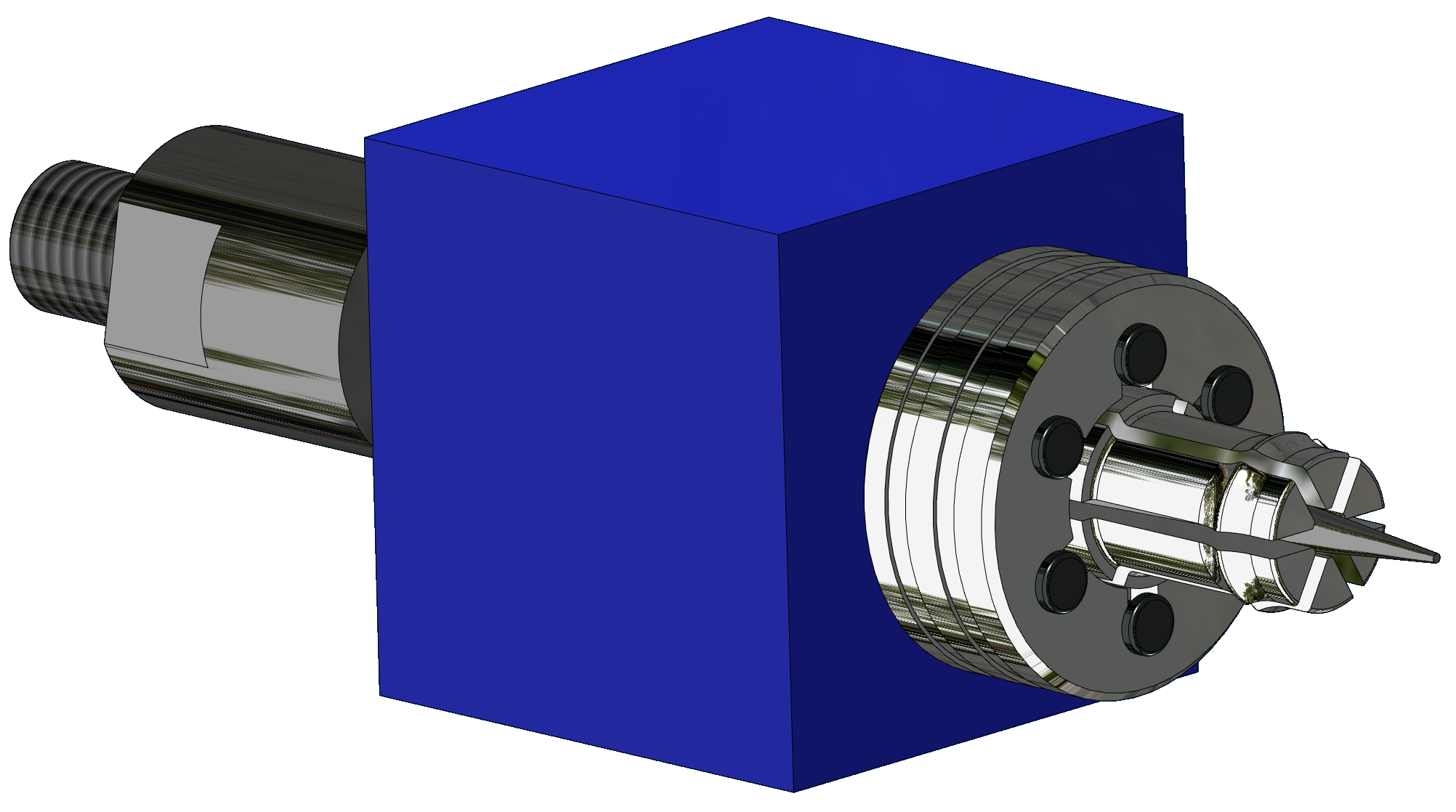

Assembly devices - Assembly devices provide the possibility of installing assembly processes. These include other technical equipment used in assembly and disassembly tools, assembly apparatus, assembly and disassembly machines centers.

Assembly machines - Assembly machines have several specific features. They carry out kinematic-demanding movements. As a result, increased demands are placed on the drive and control elements and the reliability of the individual elements and mechanisms.

Assembly

Workstation - Assembly workstation means a defined production area in

which a worker (or several workers) performs assembly operations according to

the prescribed procedure. Assembly workplaces have their specific peculiarities

based inter alia on the type of assembly.

Assembly lines

Assembly lines are designed on the basis of current

character of production. Assembly workplaces are deployed in a sequence of

assembly operations, and the assembled products advance from one operation to

the next by certain conveying devices.

We can implement electro-automatic, pneumatic, hydraulic or other elements in the assembly activities according to the customer's requirements or the degree of production automation. The activities that are currently automated by the jig are: supply, sorting, feeding to the mounting position, application of adhesive and sealant, lubrication, cooling or heating, marking and joining.

In particular, joining is one of the customer's most common requirement for the design and development of the jigs. The connection ensures a fixed relative position of the assembled parts while the mutual immobility is ensured by mechanical forces, geometric locking or a connection made on the basis of molecular forces or adhesion.