Cable assembly lines

Cable assembly lines for production cable assembly

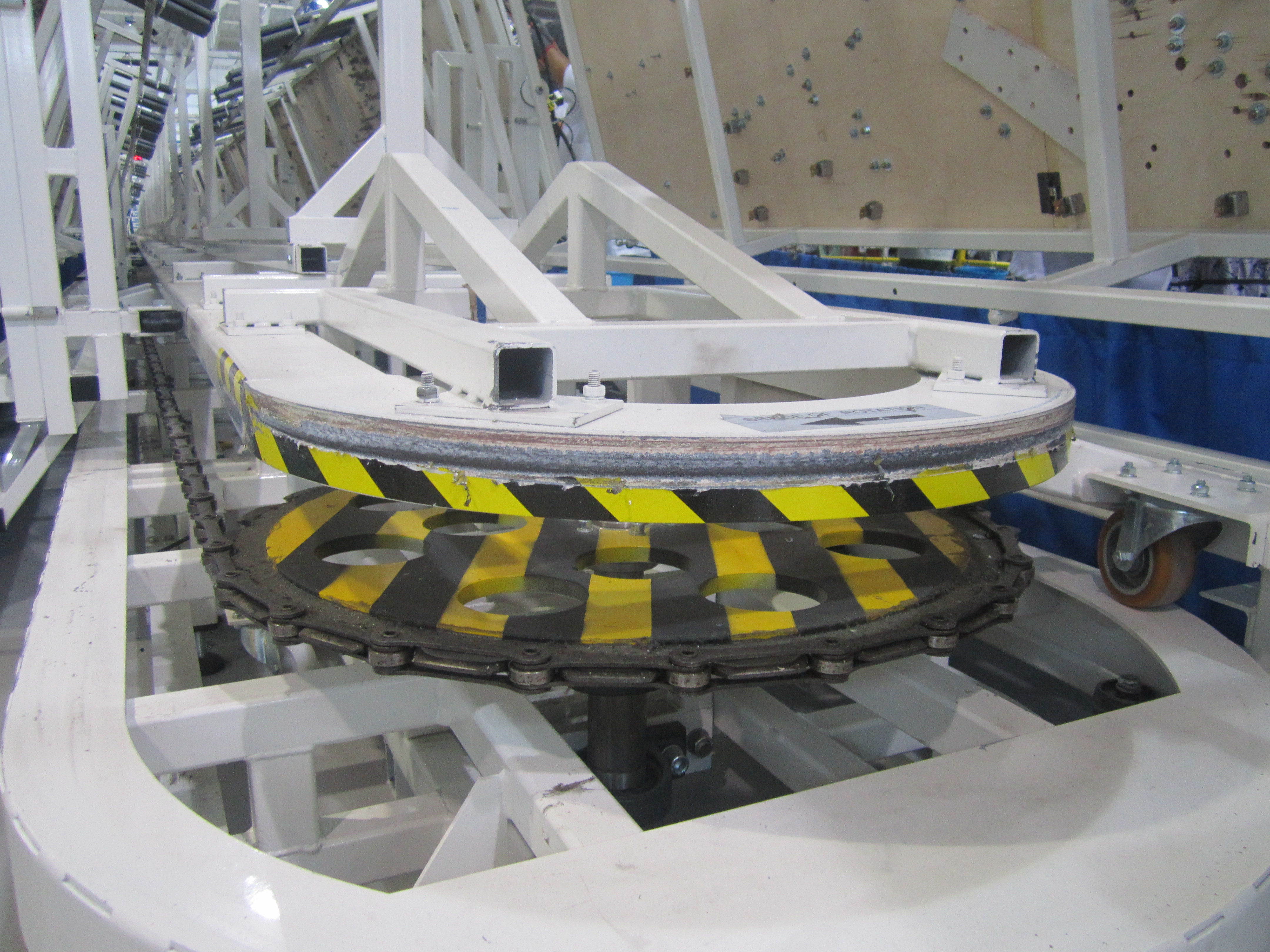

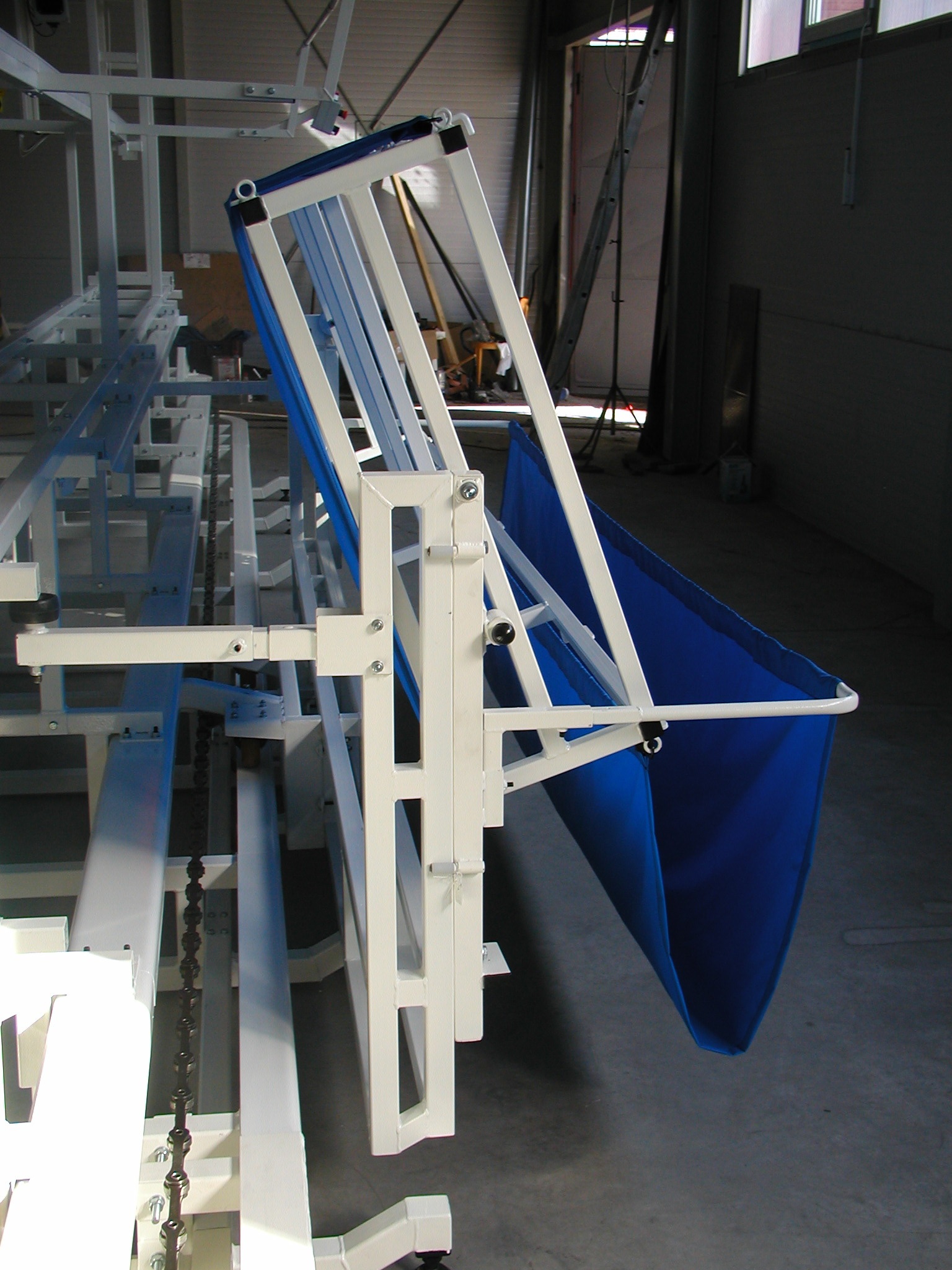

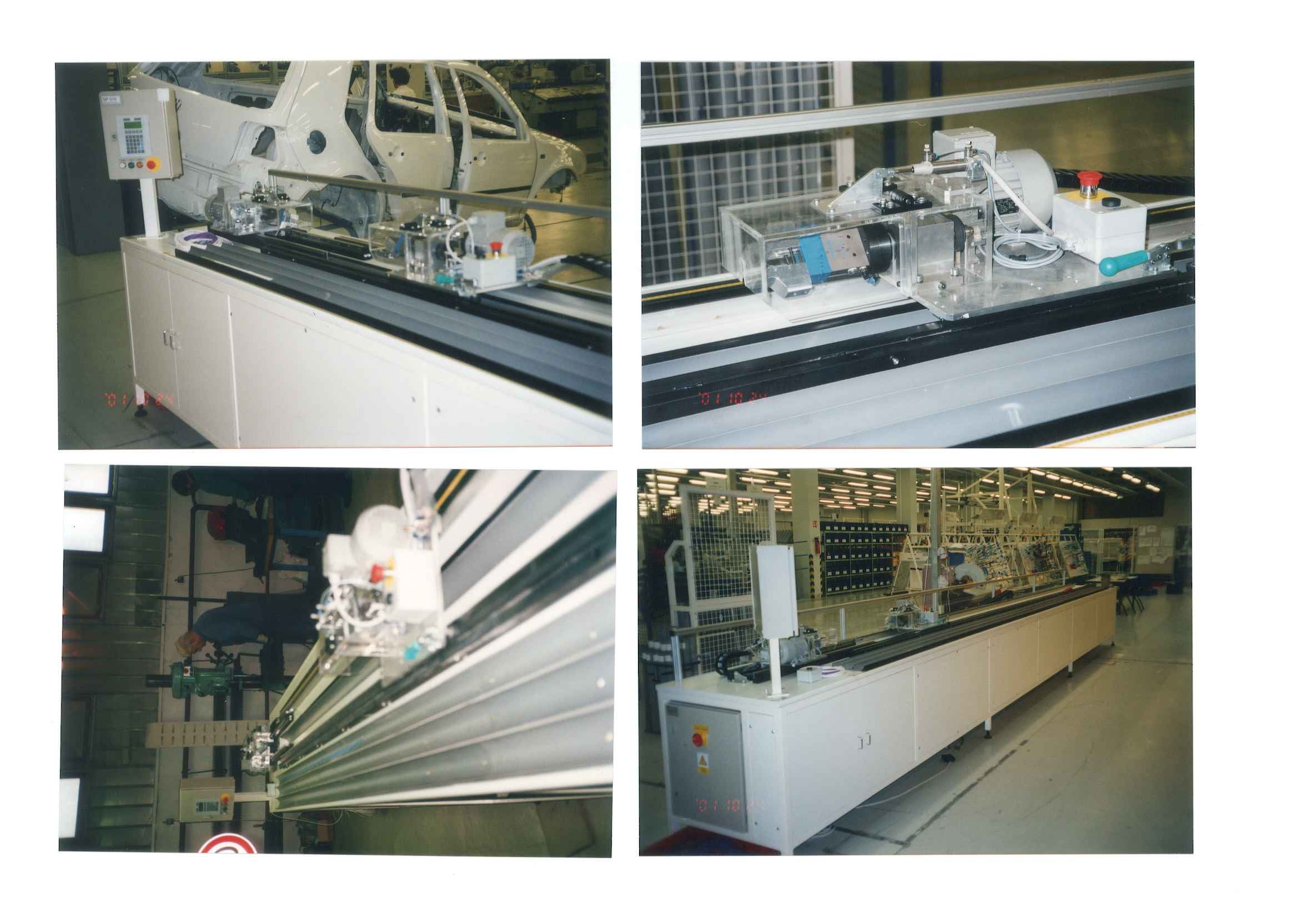

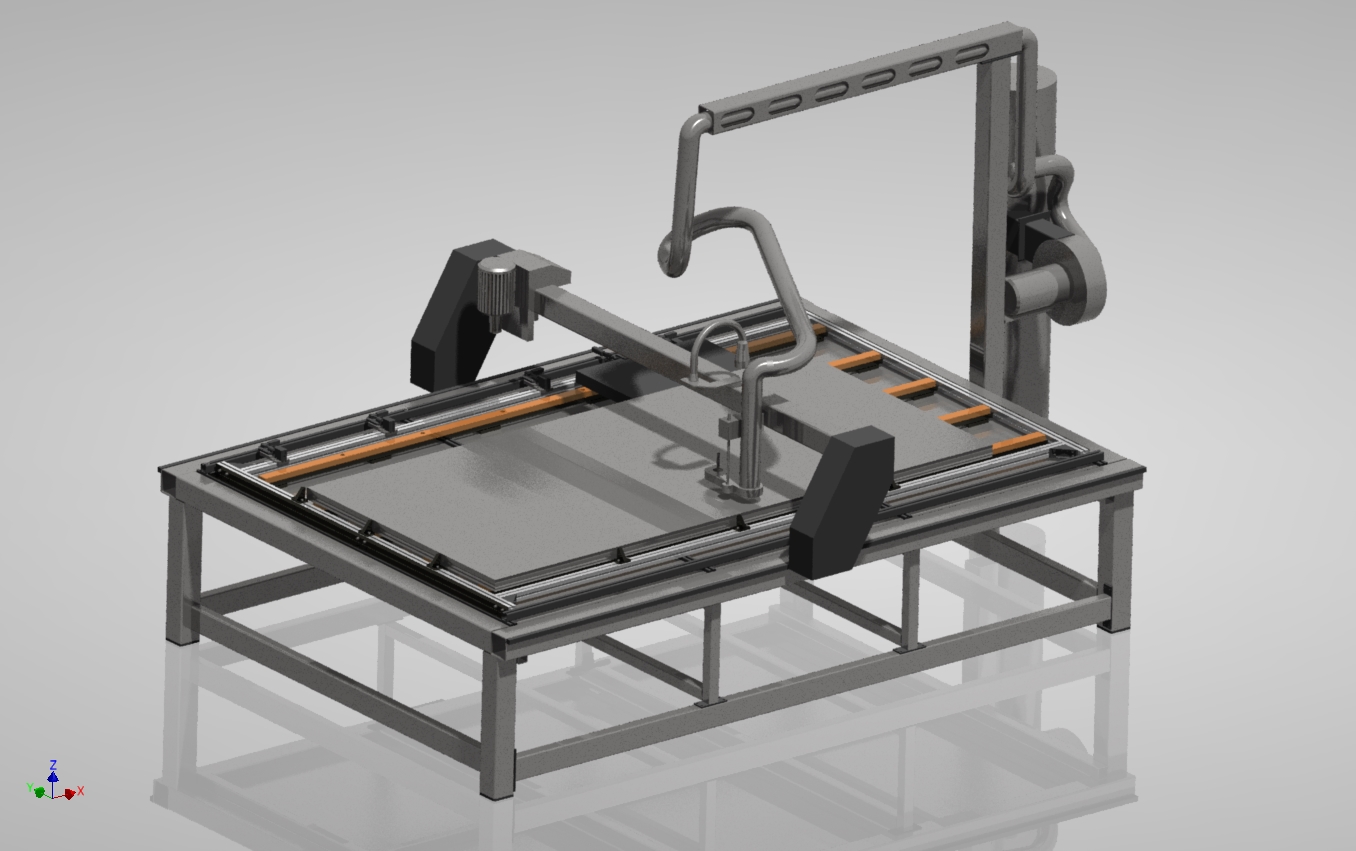

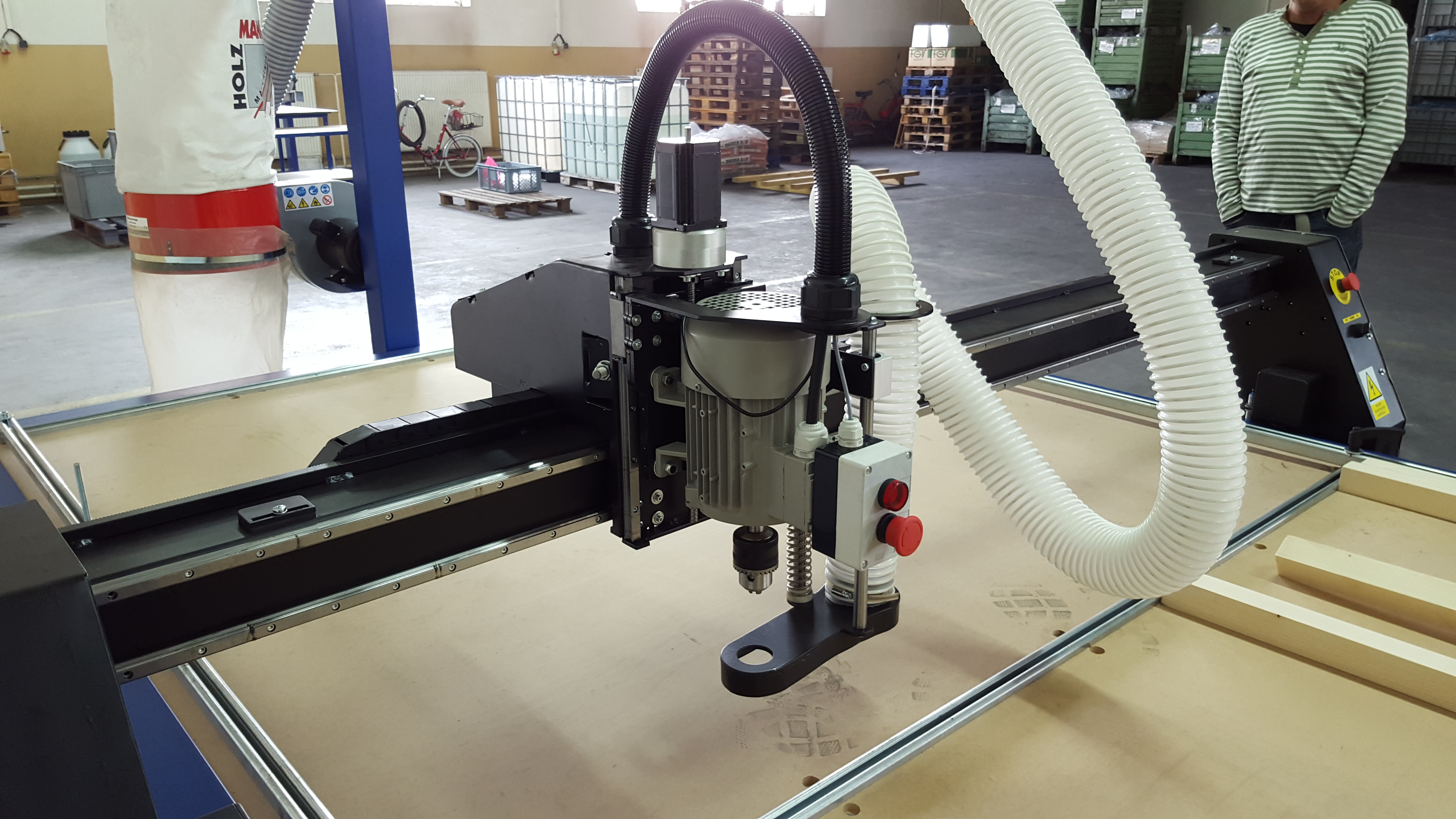

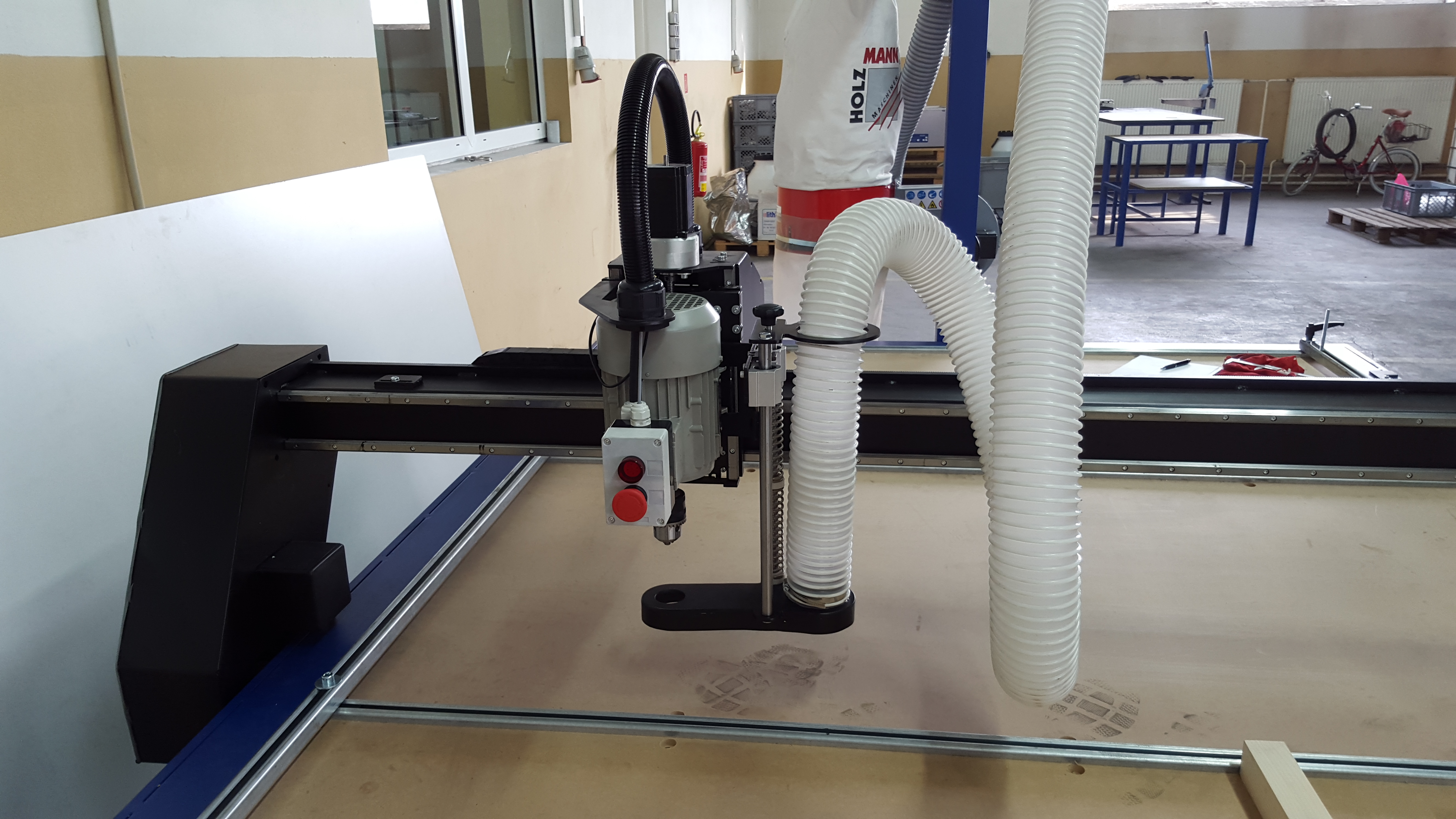

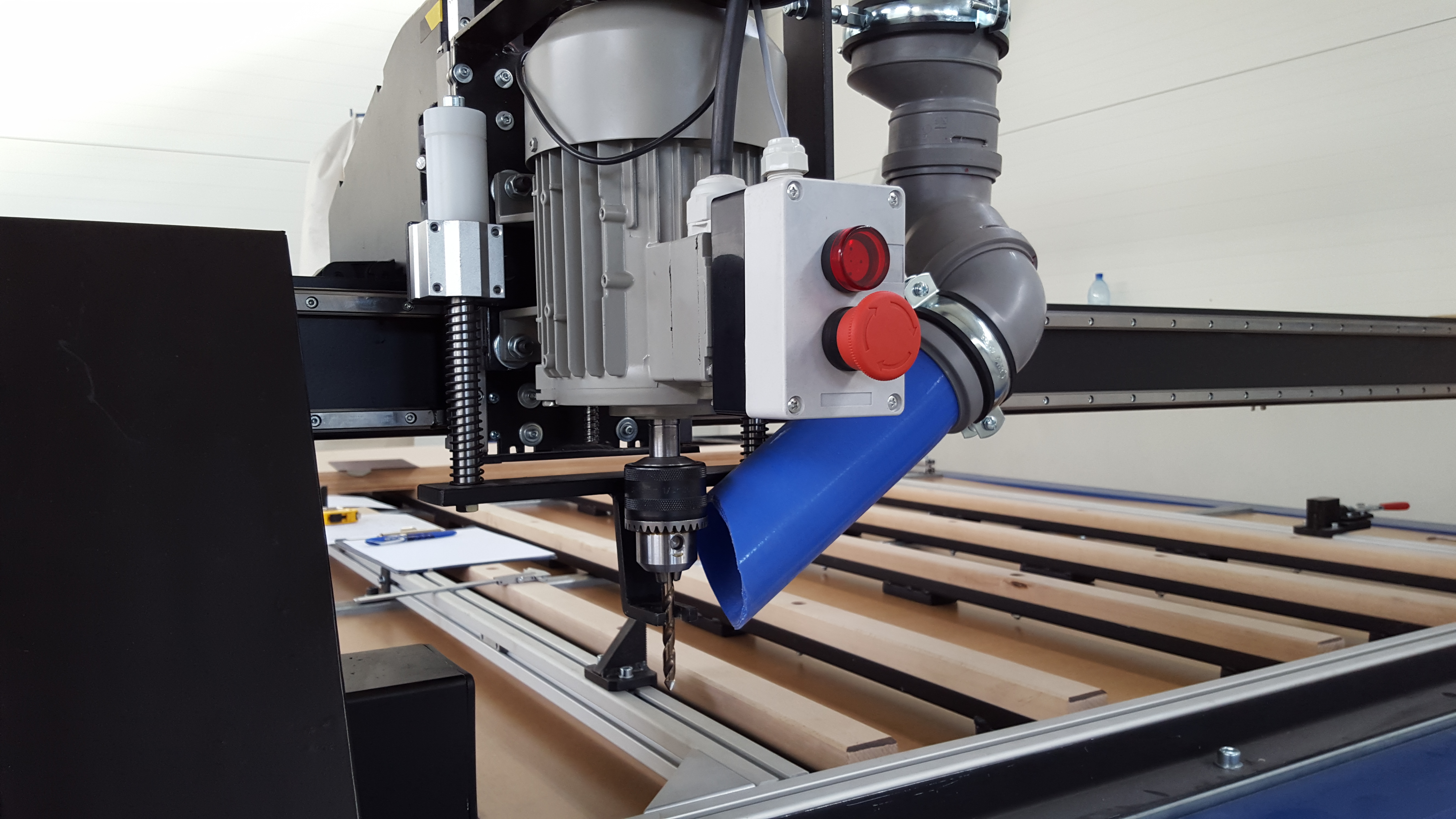

for nearly 25 years of supply have gone through a changes and extensive modernization . Today delivered assembly lines for cable assembly productions are made in many variants , witch are specific by these parameters and atributes. Trolleys of all variants are moving along the track, witch is part of the assembly line ( not on the floor of the hall

). Board carrier is able to adjust in height within the range between

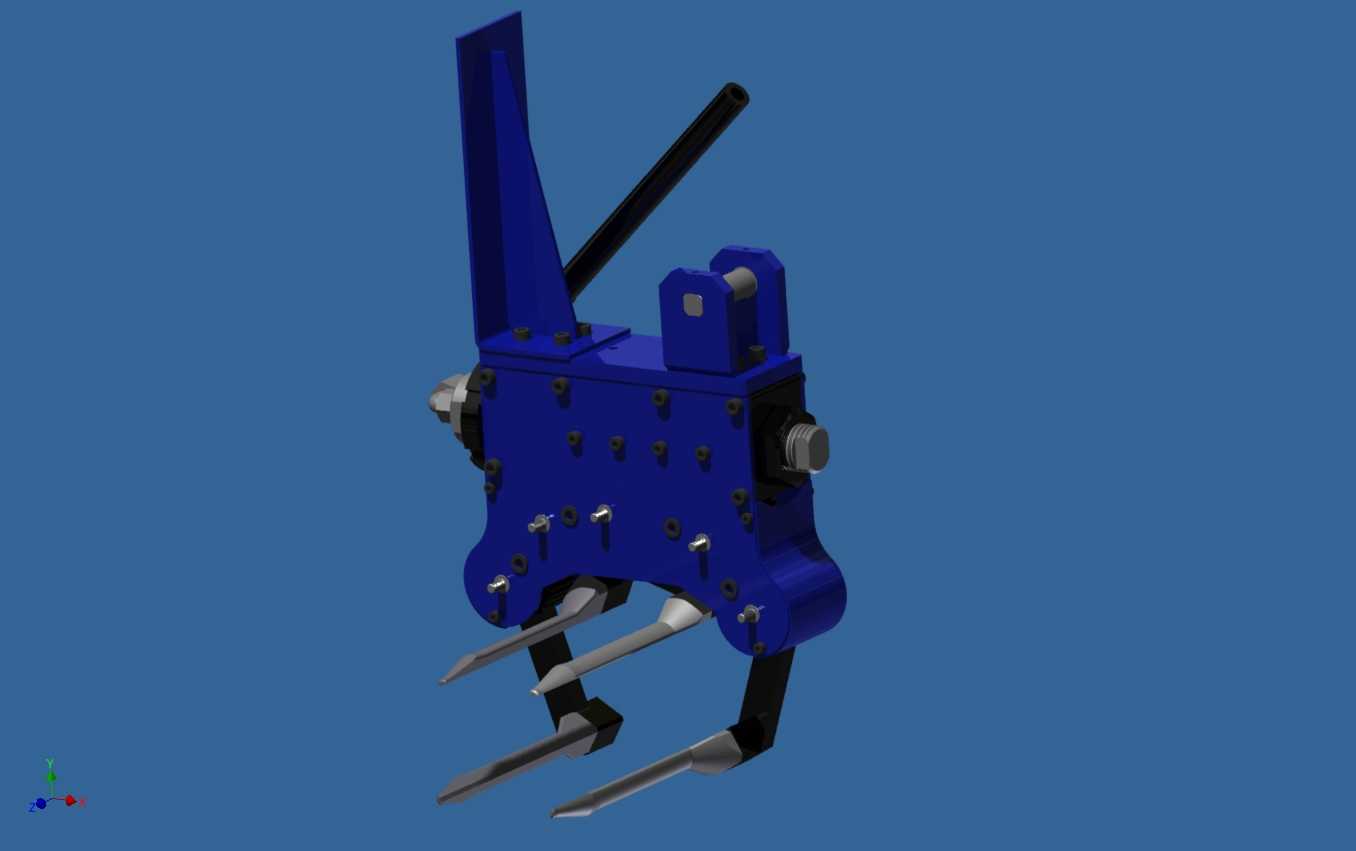

645mm -820mm. Assembly lines are made in single sided variant (on the board carrier is only board with technology ) and double sided (on the board carrier are two boards with technology , that means turing board carrier by 180 degress it is possible to fast change of another cables assemlby type ). There is also variant with extension board carrier . This variant allows to fast change of productions another type of assemlby cables witch are made on board with different lenght. The newest change is based on constriction of width bulit-up area by 400mm . Construction solutions of assembly line allow to use up to 20 boards of diferent lenghts between 1200 mm to 5000 mm.

Expect of assembly lines we delivered for these companies other devices and equipment requirment for cable assembly production like

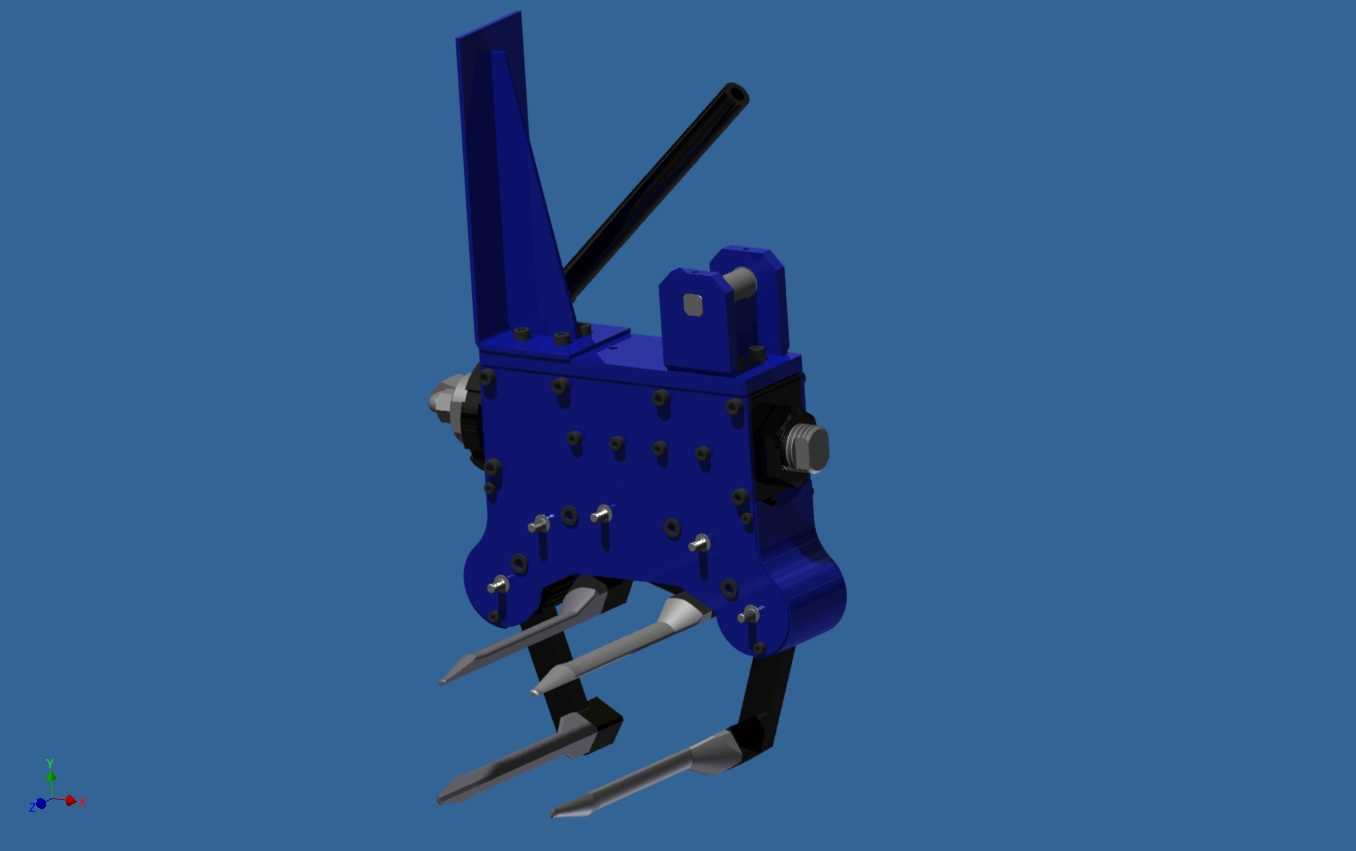

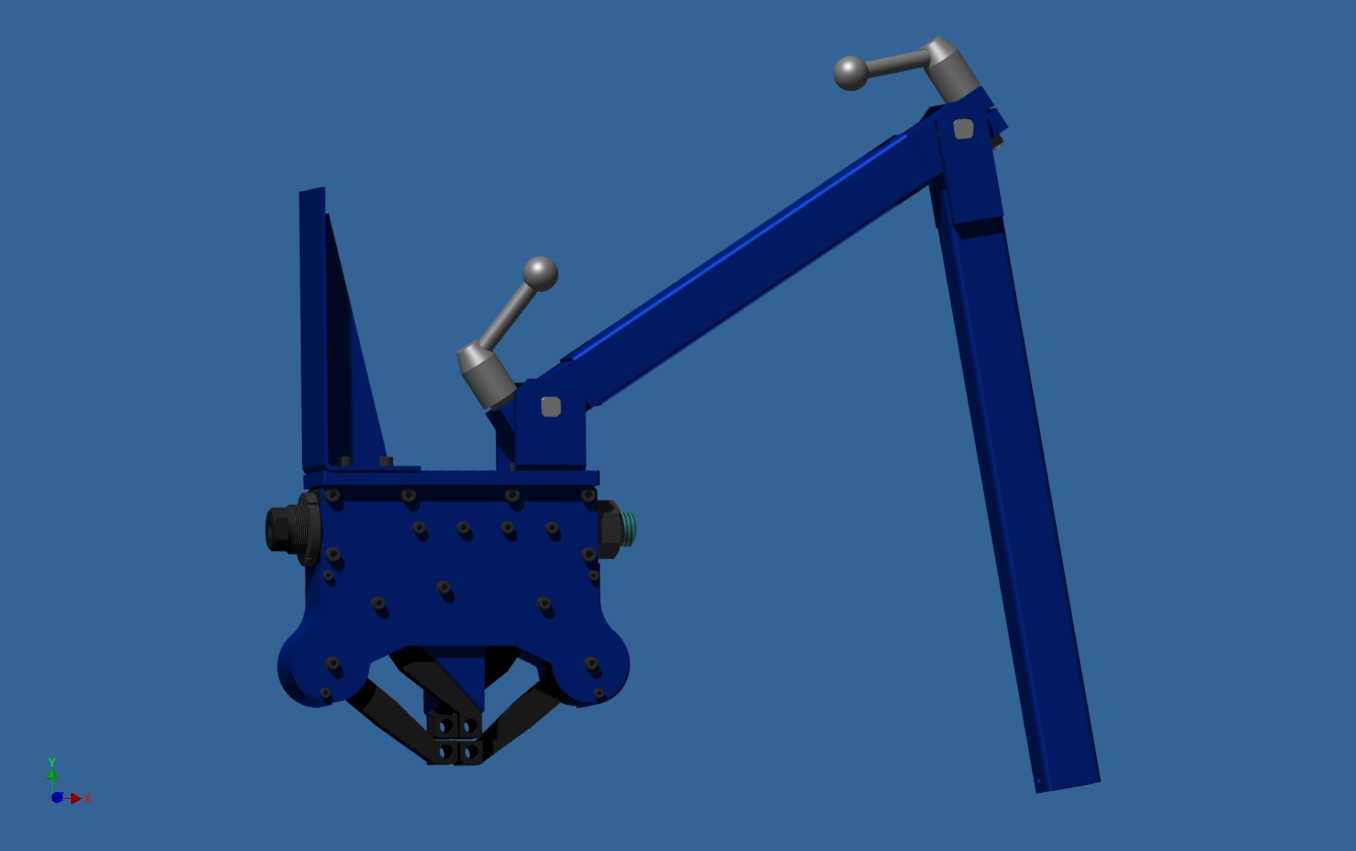

various conductors twisting devices

,

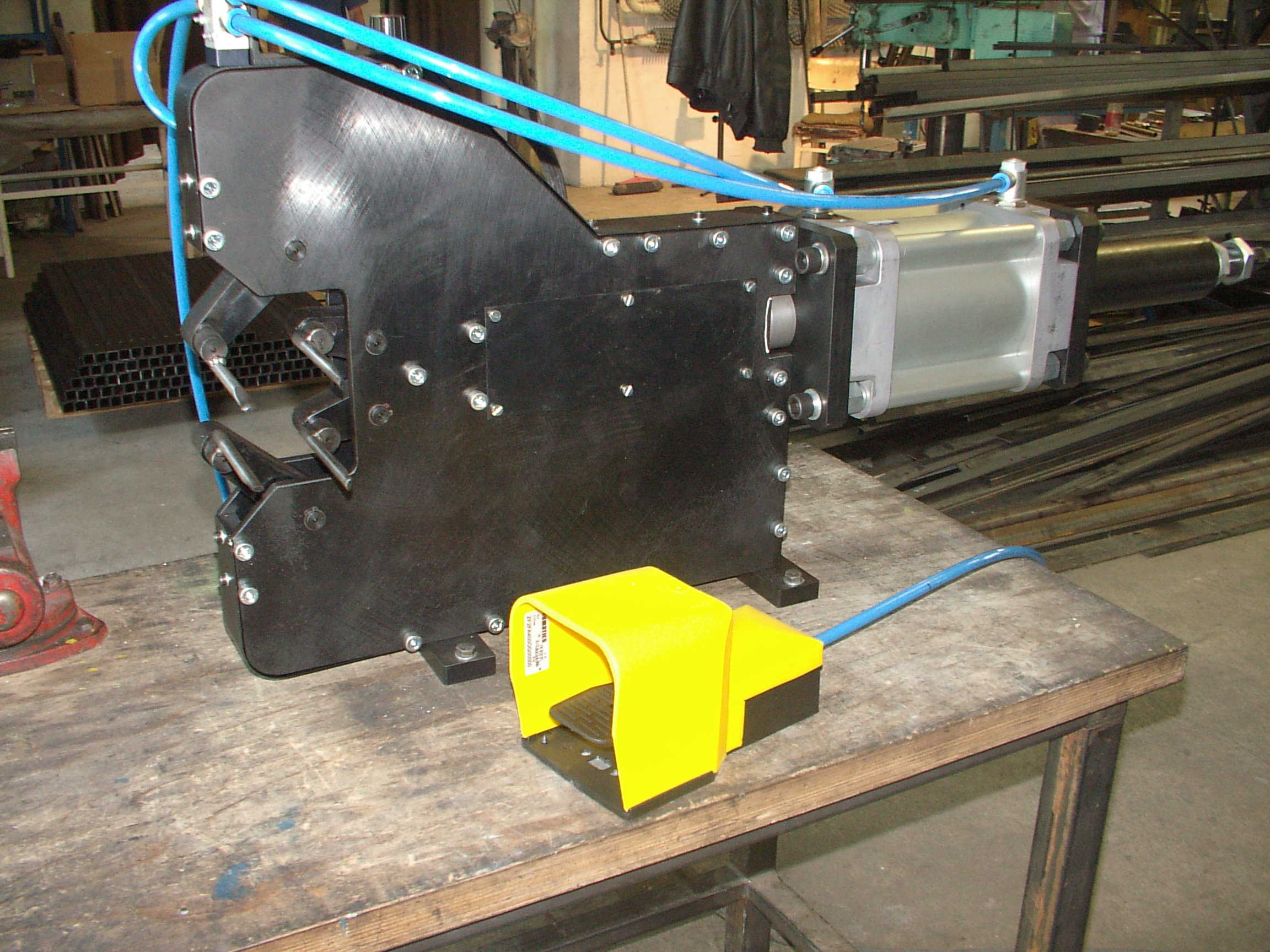

non-driven conveyors

,sealing sleeves extention devices. CNC cutters and so on.